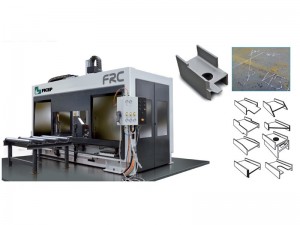

The Ficep Robot Model FRC with Laser Scanning has Proven to be up to 60% Faster than robots that have to Mechanically Probe for Each Cut!

Ficep first introduced the utilization of a robot for plasma cutting of structural shapes over 20 years ago. Since the very beginning the design featured a Cartesian Robot in conjunction with a PlasmaTorch/Oxy-Torch to perform the generation of:

- Bolt holes

- Copes

- Blocks

- Cut off

- Complex routines

Cartesian Versus Articulating Robots:

The Ficep robotic system has always centered on a Cartesian design rather than an articulating robot for several important reasons that are relevant when thermally cutting structural shapes.

- An articulating robot has to employ typically seven axes’ of simultaneous movement to accomplish structural burning operations where a Cartesian system accomplishes all movement with as few as two axes of simultaneous action.

- Since a Cartesian robot’s movements are greatly simplified all the hoses and cables that are required to support the torches are enclosed in the robotic arm so they are not exposed to damage from abrasive plasma dust, UV and sparks.

- The simplified robotic movements reduce cable whip and fatigue.

Ficep’s FRC Robot Unique Features:

- Laser scanning of the entire profile to be cut in seconds eliminates the need to probe at the start of each hole or cut.

- Automatic tool changer from plasma to oxy-fuel in 1-2 seconds makes the use of both torches practical on the same section to be processed for maximum productivity.

- Ability to process all four sides of a structural tube as standard.

- The six-axis capability of the robot gives full beveling on both the flanges and the web.

- The oxy-fuel torch generates the optimum solution for getting close to the flange for requirements such as rat holes.

- Automatic rotation of mitered parts in a nest to achieve common line cutting of miters.

- Comprehensive 3-D nesting software that combines the cut on the trailing end of one part with the cut on the leading end of the next section in a mult. This eliminates the number of starts and stops to extend consumable life and reduces cut time to the minimum.

For a marginal additional cost a CNC drill can be added to the robot so you can achieve the additional versatility of drilling (better hole quality on deeper holes, enhanced speed/efficiency and greater flexibility of locating web holes close to the flange, for example), scribing, tapping, milling, countersinking and counter boring. This can all be accomplished in roughly the same footprint and with the same operator and material handling system!

Please contact us for a free on-site consultation.

Metalfab, Inc. provides our customers with solutions to their manufacturing needs. We look forward to examining each metalworking application and developing the most efficient, cost effective method for production. Whether the solution is new or used machinery, application software, lean manufacturing, tooling or service, Metalfab will work for you to determine the best method.